Simulation in manufacturing systems

Simulation in manufacturing systems is the use of software to make computer models of manufacturing systems, so to analyze them and thereby obtain important information. It has been syndicated as the second most popular management science among manufacturing managers.[1][2] However, its use has been limited due to the complexity of some software packages, and to the lack of preparation some users have in the fields of probability and statistics.

This technique represents a valuable tool used by engineers when evaluating the effect of capital investment in equipment and physical facilities like factory plants, warehouses, and distribution centers. Simulation can be used to predict the performance of an existing or planned system and to compare alternative solutions for a particular design problem.[3]

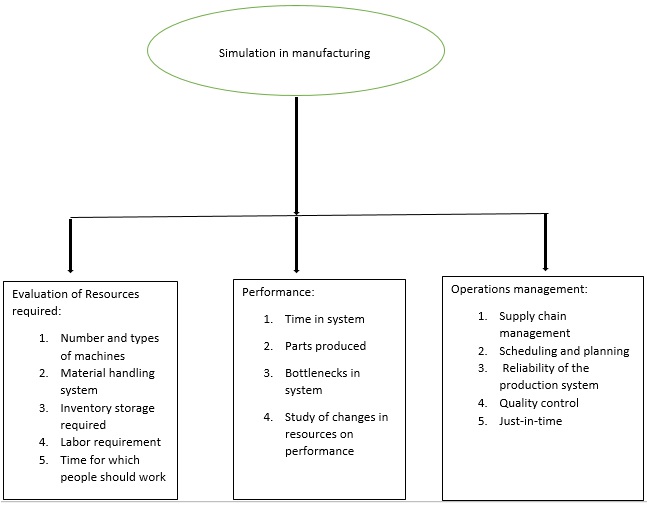

The most important objective of simulation in manufacturing is the understanding of the change to the whole system because of some local changes. It is easy to understand the difference made by changes in the local system but it is very difficult or impossible to assess the impact of this change in the overall system. Simulation gives us some measure of this impact. Measures which can be obtained by a simulation analysis are:

Some other benefits include Just-in-time manufacturing, calculation of optimal resources required, validation of the proposed operation logic for controlling the system, and data collected during modelling that may be used elsewhere.

The following is an example: In a manufacturing plant one machine processes 100 parts in 10 hours but the parts coming to the machine in 10 hours is 150. So there is a buildup of inventory. This inventory can be reduced by employing another machine occasionally. Thus we understand the reduction in local inventory buildup. But now this machine produces 150 parts in 10 hours which might not be processed by the next machine and thus we have just shifted the in-process inventory from one machine to another without having any impact on overall production

Simulation is used to address some issues in manufacturing as follows: In workshop to see the ability of system to meet the requirement, To have optimal inventory to cover for machine failures.[4]