Supply chain operations reference

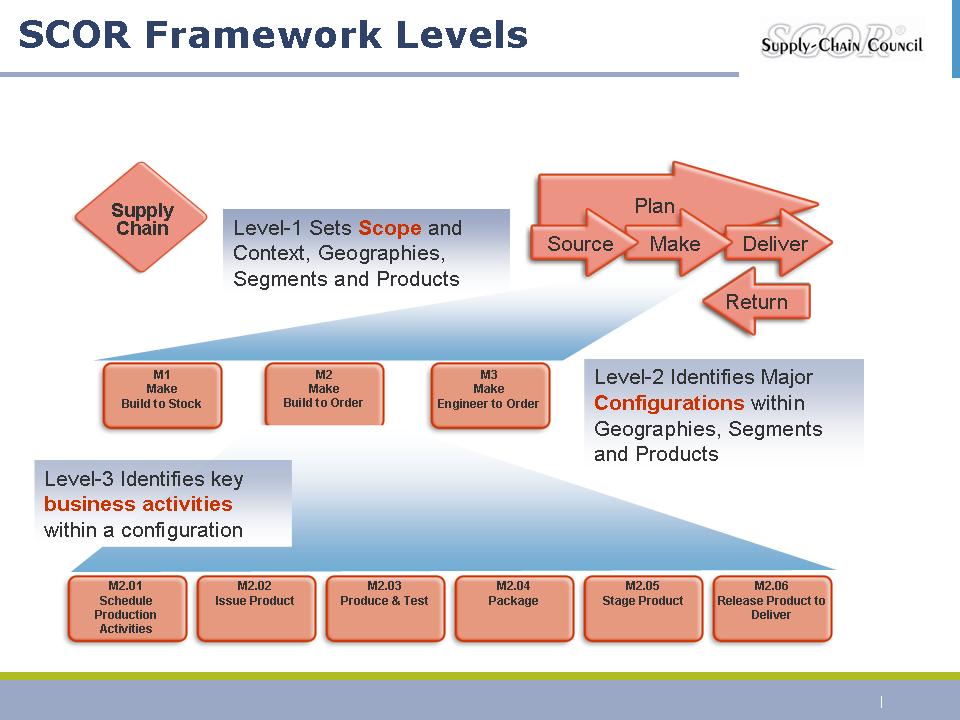

The Supply Chain Operations Reference (SCOR) model is a process reference model originally developed and endorsed by the Supply Chain Council, now a part of ASCM, as the cross-industry, standard diagnostic tool for supply chain management.[1] The SCOR model describes the business activities associated with satisfying a customer's demand, which include plan, source, make, deliver, return, and enable. Use of the model includes analyzing the current state of a company's processes and goals, quantifying operational performance, and comparing company performance to benchmark data. SCOR has developed a set of metrics for supply chain performance, and ASCM members have formed industry groups to collect best practices information that companies can use to elevate their supply chain models.

This reference model enables users to address, improve, and communicate supply chain management practices within and between all interested parties in the extended enterprise.[2]

SCOR was developed in 1996[3][4] by the management consulting firm PRTM, now part of PricewaterhouseCoopers LLP (PwC), and AMR Research, now part of Gartner, and endorsed by the Supply Chain Council, now part of ASCM, as the cross-industry de facto standard strategy, performance management, and process improvement diagnostic tool for supply chain management.

The SCOR Digital Standard (DS)[5] was released in 2019 and updated in 2022 to digitize the model to make it more accessible and then to better describe dynamic, asynchronous digital supply

chains, rather than the linear system presented by previous versions of the model. The 2022 update restructured the six major processes into the following processes:[6]

This new version of the model is illustrated as a type of infinity loop that reflects the modern

reality of supply chain networks, rather than linear supply chains and puts greater emphasis on

collaboration, visibility and the effects of market drivers. The SCOR DS model is currently available for free.

The implementation of the SCOR model helps with the utilization of the supply chain model. Companies usually integrate SCOR into their existing practices, which helps them reach their business goals and optimize their activities.[13]

A project that includes the SCOR model is usually built in these steps:

The People section includes a standard that is used for description of skills that are required to perform a specific task and to manage those processes. In general, these skills are specific to the supply chain, where some can be found as applicable outside the supply chain field as well.

Skills are defined by Trainings, Experiences, Aptitudes, and Competency level. The latter is further divided into five widely accepted competency levels: Novice, beginner, competent, proficient, and expert.

The competency levels are most commonly used as practice or process maturity levels. In addition, the job specification or a person is evaluated as the difference between the real (people) and planned (job specification) level of competency.