Tuning mechanisms for stringed instruments

A variety of methods are used to tune different stringed instruments. Most change the pitch produced when the string is played by adjusting the tension of the strings.

A tuning peg in a pegbox is perhaps the most common system. A peg has a grip or knob on it to allow it to be turned. A tuning pin is a tuning peg with a detachable grip, called a tuning lever. The socket on the tuning lever fits over the pin and allows it to be turned. Tuning pins are used on instruments where there is no space for a knob on each string, such as pianos and harps.

Turning the peg or pin tightens or loosens the string. Some tuning pegs and pins are tapered, some threaded. Some tuning pegs are ornamented with shell, metal, or plastic inlays, beads (pips) or rings.

Other tuning systems include screw-and-lever tuners, geared tuners, and the konso friction tuning system (using braided leather rings).

Pegbox or headstock[edit]

A pegbox is the part of certain stringed musical instruments (the violin family: violin, viola, cello, double bass) that houses the tuning pegs. The corresponding part of the lute family (including guitar, mandolin, banjo, ukulele) is called the headstock.

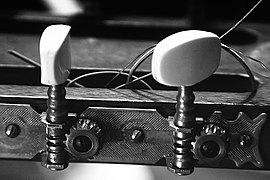

Pegs for double bass and guitar family instruments are usually geared, and are called tuning machines or machine heads. They often use a worm gear. The gearing ratio varies; while higher ratios are more sensitive, they are also more difficult to manufacture precisely. Machine heads may be open, with exposed gears, or closed, with a casing around all the gears.

Geared pegs for violin family instruments also exist, although they have not gained wide use, which has to do with the extensive and irreversible physical modification that must be made to the peg box in order to mount them, which is often viewed as ruining the aesthetics of the instrument, combined with a bad reputation they acquired due to poorly designed early models that were prone to failure, often with catastrophically damaging results.

The most recently marketed pegs of this sort use planetary gears designed to fit inside a case shaped like a friction peg. They have seen some adoption as they look almost exactly like friction pegs, require no more modification of the instrument than a new set of friction pegs, and make fine tuners unnecessary. They are also durable and less sensitive to changes in temperature and humidity.[12] They are popular on banjos.[13]